More about Thimbles

From Jiangling to Nürnberg

Magdalena and William Isbister.

(for a more detailed narrative of early thimble making the reader is referred to Holmes (1).)

In the Iron Age, the cultures of Europe, India and the Middle East were concerned with the development of wrought iron. It was in China that the metal smiths of the day began to cast iron, and it was not long before hardened steel was being made by the process of a ‘hundred refinings’ (2). Prior to the discovery of steel, fine metal needles had been made of iron or copper but they were very soft and did not withstand strong pressure so that there was no need for any sort of pushing tool. The advent of steel allowed very fine strong needles to be made and this necessitated the invention of a light ‘pusher’ which initially took the form of an open flat band like a finger ring (Fig 1, left). We have not been able to identify such a thimble, however, but a cast, flat band thimble has been identified from an archaeological excavation in Scythia. The thimble (Fig 1, right) was found in a Scythian settlement along with silver coins minted in the 2nd century BC (3).

Fig. 1

A single steel needle from the time of the Han Dynasty (206BC - 202AD) was found in a tomb in Jiangling, and it must be assumed that thimbles were in use at this time, although no thimble seems to have been discovered with the needle. During the Cultural Revolution, in the tomb of a Han Princess, in Mawangdui, Hunan Province, steel needles and a thimble were found together (1).

Over the succeeding years the Han expanded into Central Asia and trading routes, the so-called silk routes (‘silk road’), opened up to the north west of the Han Empire and eventually reached Damascus and Antioch. From these eastern Mediterranean ports goods were taken further west by sea to Constantinople and Rome. Needles followed the silks and thimbles followed the needles.

Han needle rings were found in Puli (Tashkorgan), along the silk route, and are similar to those found in Byzantine excavations in Antioch and Corinth (4).

Fig. 2

These thimbles (Fig. 2) were found in Turkey and are similar to those thimble rings found in Puli. They are made of cast bronze and date between the 9th and 12th centuries.

Fig. 3

In Russia it used to be the custom to bury women with their thimbles and sewing tools so that early thimbles were often found in association with female burial sites. In a 14th - 15th century site close to Perm on the Kama river, jewellery, a coin dated to the mid 14th century and a thimble were discovered. The thimble was conical in shape with an open top and hand indentations. It was made from a copper alloy sheet and had a soldered seam (Fig. 3). Similar thimbles were discovered in Astrakhan further to the South-West of Perm. The thimbles date to the time of the Golden Horde and may have evolved from the same method of manufacture used in China and Scythia many centuries earlier. Pelham Burn and the Dutch Thimble Club (5, 6), however, think that this type of thimble was made in Nürnberg in the 15th or 16th century. We favour the Golden Horde origin because more of these thimbles seem to have been found in Russia than in Europe where they seem to be very rare.

For some unknown reason the Romans do not seem to have used metal thimbles for sewing (7). There is no known explanation for this; it may be that leather and material finger guards proved to be sufficiently robust and malleable for the purposes of the Romans. To this date there has been no well-documented archaeological data to link metal thimbles to any Roman site ever excavated. There are what are claimed to be ‘Roman thimbles’ in museum collections but the provenance, if any, of these thimbles is not robust and many have recently been removed from display, so that it must be concluded that metal thimbles, as we know them, were never used in the Roman Empire.

There is thus a gap of some hundreds of years since the use of the thimble in China and it’s reappearance along the silk route. Fine steel needles were rare and expensive, and it may just be that there were not many people who needed to use a metal thimble for many years?

The silk route extended through what is now known as Afghanistan, and as the use of the thimble extended towards the west so the shape changed slowly too.

Fig. 4 Fig. 5 Fig. 6

These three thimbles were found in Northern Afghanistan (Figs 4, 5, 6). The left hand thimble is open topped and derives from the open rings of China. It is cast bronze and probably dates to the 10th century. The second thimble, is a little later, is also cast but now has a top. There are also three crescents around the rim. The third thimble may be a development of the second thimble, in that the three rim crescents now extend up to the top of the thimble where there is a small knob. The thimble is very similar to those excavated at Hama in Syria (Fig. 8).

Fig. 7 Fig. 8 Fig. 9

The thimble in Figure 7, similar to the thimble shown in Figure 5, was found in Afghanistan and has a distinct rim. These thimbles with a chevron motif separating three hand-dimpled panels (Figs .5-8) are called Hama thimbles (Abbasid-Levantine (8)) after the town where two were found during a Danish pre WW ll excavation (9, 10). They were dated to between the late 12th and 14th centuries so that an ‘Abbasid’ connection seems unlikely in relation to these two thimbles. The earlier Afghani thimbles (Fig. 5-7), however, may have been made during the time of the Abbasid Caliphs in Baghdad.

The spread of Islam is intimately linked with the further journey westwards of the humble thimble. As the Arab armies moved west and Islam spread to North Africa and Spain so did the thimble. It was a different and much heavier work thimble (Fig. 9) and was most probably used for heavy sewing such as sail making or leatherwork. Lighter thimbles have not been found along side of these heavy thimbles, and this may be because the Prophet did not value personal adornment and there was thus no need for the use of fine steel needles. Any personal sewing undertaken at the time may have been supported by leather or material finger guards (Fig. 10).

The thimble shown in Figure 9 is a cast iron thimble. It was found in Bulgaria and dates to the 12th or 13th centuries. It may be the forerunner of the so-called ‘ Turko-Slavic’ thimbles (Figs. 11-16).

Fig. 11 Fig. 12

Fig. 13 Fig. 14 Fig. 15

Fig. 16

The Turko-Slavic thimbles were heavy and bulbous. Dimpling was made by hand and the thimbles were cast in either bronze or iron (Fig. 15). They often had ventilation holes and or a six-pointed star at the top and were sometimes grooved around the rim. They date from about the 12th/13th century.

In North Africa and Spain a different type of heavy Islamic thimble has been found. Their appearance mirrors the development of the forging of steel, brought to Cordoba by the Moors from Damascus, and the manufacture of steel needles in Spain. The thimbles are usually cast in bronze, although these thimbles have been found in both silver and gold and they date from the 10th century. They may have long pointed tops and often a decorative band; sometimes they have an ancient Arabic inscription. They have been called ‘Hispano-Moresque’ and Pelham Burn has described three types (11).

Fig. 17 Fig. 18 Fig. 19

Type 1 thimbles are tall, elegant and have a decorated band above a rounded rim (Fig. 17). They have been made in cast bronze, silver and gold. Type ll thimbles are tall but not so well made and thinner because they are hammered and drawn and have a side seam (Fig. 18). Type lll thimbles are shorter and cruder and usually have a hole in the top Fig. 19).

Other ancient thimbles are still being dug up in Northern Spain and Southern France and are heavy and have rather thick walls and flat tops. They probably date from the 16th century and are frequently decorated with multiple fleur de lis patterns and decorated tops (Figs. 20-24).

Fig. 20 Fig. 21 Fig. 22

Fig. 23 Fig. 24

Thimbles probably arrived in Europe proper either through Spain to France or directly from the Middle East with the returning Crusaders. The Crusades were a series of religiously sanctioned campaigns that were waged by much of Christian Europe, particularly the Franks, to restore Christian control of the Holy Land. Steel needles, and thus the need for thimbles and thimble makers, may have spread into France through Northern Spain but more probably were directly brought back to France by returning Crusading Knights.

By the 13th century thimble making was well established in France and clearly occurred independently of the thimble making industry in Nürnberg with which there was no known communication at the time. Buckle makers (Fremailliers) were allowed to cast brass/latten thimbles in France, whereas the button makers (Boutonnièrs) were allowed to make thimbles by deep drawing sheets of copper (Fig. 25). Malleable bronze alloys were not known at this time.

Dimpling was undertaken by hand (Figs. 26-28). Many French thimbles of this time have triangular shaped dimples (Figs. 29-32).

Fig. 26 Fig. 27 Fig. 28

Fig. 29 Fig. 30 Fig. 31 Fig. 32

Figures 26 to 32 show cast thimbles and finger rings found in France dating between the 13th and 16th centuries.

Milan was also recorded as a centre for thimble production in the fifteenth century. Italian thimbles were recorded in the inventory of Queen Charlotte, second wife of Louis Xl, but no examples of these thimbles are known now (12).

Nürnberg was established as a frontier fortress in 1039 and, as decreed by the Emperor Charlemagne some two hundred years before, was staffed by all those craftsmen necessary to provide and maintain all the goods needed by a royal household (13). Many Crusading knights returned to their castles to find that as the craft guildsmen and city merchants became richer they, the aristocrats, were becoming poorer. They took to robbing the merchants’ goods as they left the city in caravans and became know as the ‘robber barons’. The first reference to a German thimble was made in the 12th century (14) and the first reference to thimble making in Nürnberg dates from 1373.

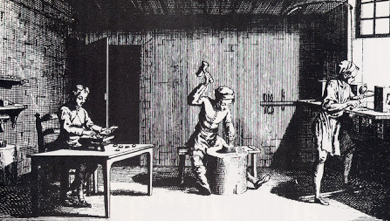

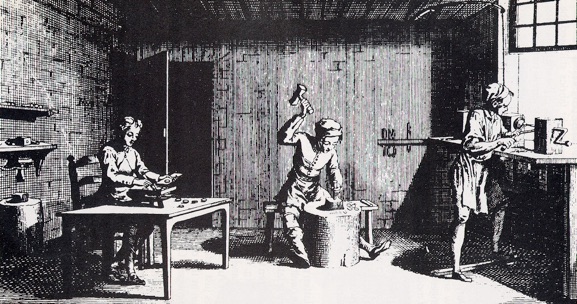

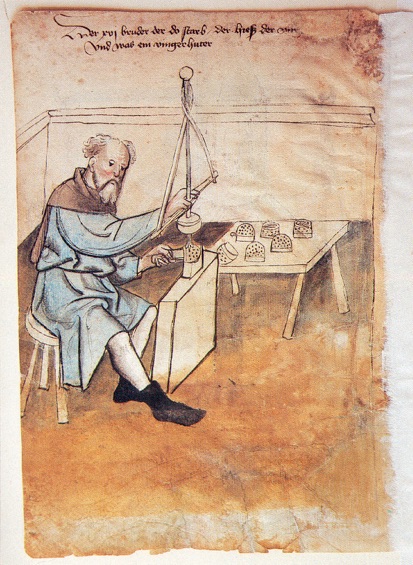

Fig. 33. ‘ving[...]’, a thimble maker, drilling the indentations into a cast brass thimble

Initially, when thimbles were cast, thimbles were made by the copper workers or ‘redsmiths’. Thimble makers, some of whom may have ‘finished’ the cast bronze thimbles (Fig. 33) obtained from the redsmiths, were, at first, regarded as free tradesmen but they soon wished to be members of a guild of their own. In about 1530, they were incorporated with the coppersmiths. Later when casting was replaced with deep drawing they were allowed to form their own guild (15).

Fig. 34 Fig. 35 Fig. 36 Fig. 37

The early Nürnberg thimbles were stubby and cast and the indentations were made by hand, using a stamp or punch (Fig. 34). Some of these cast beehive thimbles or ‘skeps’ as they were known in England, had a hole in the top which was probably a result of the casting process (Fig. 35). Some thimbles had a clear top or ‘tonsure’ (Fig. 36) but this method of dimpling was abandoned in the middle of the 17th century. Some cast thimbles were trimmed on a lathe and these thimbles often have an indentation in the rim for securing the thimble to the lathe (Figs. 37, 42). Some cast thimbles have a distinct rim (Fig 38).

Fig. 38 Fig. 39 Fig. 40 Fig. 41

Rarely the beehive thimbles were decorated (Figs. 39, 40) and some were cast in an octagonal mould (Fig. 41).

Fig. 42 Fig. 43 Fig. 44 Fig. 45

These three cast brass thimbles (Figs. 43, 44, 45) were indented by the use of a hand drill (Fig. 33) and the dimpling is thus heavy and irregular.

In the 16th century, purified zinc became available and when alloyed with copper yielded a brass that was refined and malleable. The metal was rolled into a flat sheet, small disks of metal were cut and then these were hammered into a cup shaped mould. This process is known as ‘deep drawing’ and the dimples were then added by hand by the master thimble maker (Figs. 50, 51).

Fig. 46 Fig. 47 Fig. 48 Fig. 49

Often deep drawn thimbles show crease marks formed as the disk of brass is hammered into the mould (Figs. 46, 47). It appeared that on some occasions, two disks were hammered into the same mould at the same time (Figs. 48, 49)!

Fig. 50

Fig. 51

Members of the thimble makers’ guild were subject to strict control. Members were not allowed to travel with their tools outside of Nürnberg unless they had special permission. In this way the secrets of thimble making were retained within the town, and this may be why Nürnberg dominated the manufacture of thimbles in Europe for centuries. The thimbles, on the other hand, were exported all over Europe and often overseas through the port of Venice (16). Many Nürnberg thimbles have been excavated in sites all over England and this is cited by some (17) as evidence for their manufacture in England. As far as we know there has been no definitive evidence to show that beehive thimbles or ‘skeps’ were actually made in England. There was no brass making industry in England at the time, and the only brass available to make thimbles would have had to come from scrap brass imported as other objects. Further evidence against their manufacture in England comes from the absence of casting facilities, lathes for finishing the cast thimbles and either drills or punching equipment for the indentation. It is most unlikely that had such facilities existed in England at the time there would be no remains or records of their existence. Many ‘skeps’ are deep drawn and this skill did not exist in England at the time and neither did the malleable brass necessary for the technique. There is good documented evidence that thimbles were imported into England from the continent of Europe in large numbers in the 15th century (16, 18) and it is our feeling that it is these thimbles that are so frequently found by metal detectors and excavated in England. They were probably not made in England.

Fig. 52 Fig. 53 Fig. 54

Thimbles in Nürnberg gradually evolved away from the beehive shape (Figs. 52, 53) and in 1537 when the thimble makers’ guild was formed each master was expected to make his mark (Fig. 54) on every thimble made by him.

Fig. 55 Fig. 56 Fig. 57

Thimbles were still cast (Fig. 55) but both cast thimbles and deep drawn (Figs. 56, 57) thimbles became taller as the workers became more skilled.

Fig. 58 Fig. 59 Fig. 60

The shape of the indentations became more varied (Figs. 58, 59, 60).

Fig. 61 Fig. 62 Fig. 63 Fig. 64

Sewing rings were also made in Nürnberg (Figs. 61, 62, 63, 64).

Fig. 65 Fig. 66

It is not easy to date thimbles exactly but one guide that may be helpful is the direction of the hand-indented spiral. Masters usually started to stamp the indentations above the rim and then to proceed in a spiral direction towards the top of the thimble. The maker’s mark (when used) was usually placed at the beginning of the spiral. Thimbles with left spirals were made late in the Middle Ages (Fig. 65) whereas thimbles with a right spiral (Fig. 66) were made in the 16th century century (19). The thimble in Figure 66 was thus made in the 16th century, but since there is no maker’s mark, before 1537.

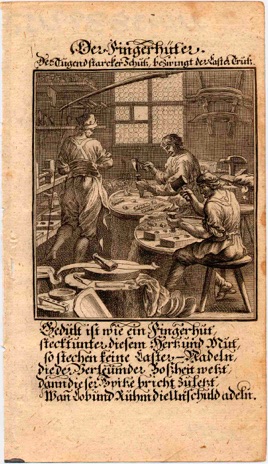

The peak period for thimble production in Nürnberg was probably the 16th century. The taller thimbles allowed more space for decoration. The strictness of the guild system prevented innovation in relation to production methods, and the increasing competition from a more mechanised fledgling industry in Holland saw the decline of thimble making in Nürnberg in the 17th century.

Fig. 67 Fig. 68 Fig. 69

A variety of complex designs were introduced before the art of thimble making abandoned Nürnberg. Pelham Burn (20) has classified thimbles from this period into four groups:

Type l – early 16c - thimbles were quite short with slightly pointed tops and simple decoration (Fig. 67).

Type ll - mid 16c - thimbles were taller, still retained their pointed tops and the decoration was more complex. They may have hearts (Fig. 72) or engraved figures (Fig. 73) or inscriptions Figs. 74, 75).

Type lll – late 16c – thimbles were taller but the tops were flat and the decoration was more complex (Fig. 68).

Type lV – early 17c – still taller thimbles with flat tops and at least two decorative bands (Fig. 69).

Fig. 70 Fig. 71

These two thimbles (Figs. 70, 71) are also probably Type ll thimbles, the one on the left has a petal top and the one on the right has three ‘trefoil’ holes.

Fig. 72 Fig. 73 Fig. 74 Fig. 75

The inscription on the band of the thimble in Figure 74 reads "Rettlich und frum ist mein reigdum” - Honesty and piety is my fortune. The inscription on the band of the thimble in Figure 75 seems to be ‘R A E V S S II E’ but is difficult to identify all of the letters.

In the mid 16th century silver became more plentiful in Europe. People who would have bought the best Nürnberg brass thimbles could now have their thimbles made in silver or gold and many had inscribed messages around the rim. Nürnberg thimble makers also devised a two-part thimble that consisted of a gilded thimble with a detachable top (Fig. 76). Under the cap and on the top of the thimble was a small painting of a person or coat of arms and this was covered with a glass or crystal protection. A third element of the thimble was a filigree covering which slid on to the base. Often the filigree part is lost and the picture has faded so much that the image is impossible to decipher.

Fig. 76

Fig. 77

Another more elaborate Nürnberg thimble, also made of silver with a glass or crystal top, has a flower engraved into the top for use as a seal (Fig. 77). Below the glass/crystal is a family crest with the date 1580 and the letters ‘VMN’ which represent the abbreviated motto ‘vergess mein/mich nicht’ (forget me not). The crest probably belongs to the Familie Frentzel. In the original state the top would have been protected by a silver cap which has been lost. The thimble itself is decorated with two bands of flowers above a motto ‘was got bescherdt ist umerwerdt 1579’. This may be translated to mean that what God wills cannot be undone. There is a clear maker’s mark on the rim. There was no filigree sleeve on this thimble.

Whilst some silver and gold thimbles were made in Nürnberg (Figs. 76 and 77), the rise of the more mechanised and thus cheaper brass thimble industry in Holland and the desire for thimbles of other precious metals led to the final demise of the Nürnberg brass thimble industry at the end of the 17th century. Nürnberg’s long dominance over the manufacture of thimbles in Europe was finally over.

-

*The remainder of the thimble maker’s name is unreadable in the original plate

Acknowledgement

We should like to thank Dr Christine Sauer of the Stadtbibliothek Nürnberg for her time and help in identifying the crest and for translating the motto from ‘old German’ on the thimble shown in Fig. 77.

We also thank Irena Sotnikova for allowing us to reproduce Figure 1.

References

1. Holmes EF. A history of thimbles. London: Cornwall Books, 1985.

2. Holmes EF. Thimble Notes and Queries 1990; 5: 6.

3. Klechinov VN. Scythian thimble. http://thimbles.ru/page.php?51

4. Davidson GR. Corinth, Results of excavations conducted by the American School of Classical Studies. 1952; Xll: 175.

5. Pelham Burn D. Early Thimbles. Thimble Collectors International, 2001. pp. 42.

6. Dutch Thimble Club. Excavated Thimbles. TSL Magazine 1995; 5 (6): 4.

7. Mills N. The History of Early Thimbles. TSL Magazine 1982; 1(4): 9.

8. von Hoelle JJ. Thimble collector’s encyclopedia. Illinois: Wallace-Homestead Book Company, 1986. pp. 29.

9. Plough G, et al. Hama, Fouilles et Recherches 1931- 1938 lV3. Copenhagen: Fondation Carlsberg, 1969. pp. 86.

10. Holmes EF. Thimble Notes and Queries 1991; 11: 12.

11. Pelham Burn D. Early Thimbles. Thimble Collectors International, 2001. pp. 16.

12. Holmes EF. Thimbles. Dublin: Gill and Macmillan Ltd, 1982. pp. 10.

13. Greif H. Talks about thimbles. Universitatsverlag Carinthia. 1984. pp. 27.

14. Holmes EF. A history of thimbles. London: Cornwall Books, 1985. pp. 24.

15. Greif H. Talks about thimbles. Universitatsverlag Carinthia. 1984. pp. 35.

16. Holmes EF. Thimble Notes and Queries 1990; 6: 2.

17. Warrington R. Early English Thimbles. TSL Magazine 2004; 9 (6): 4.

18. Holmes EF. Thimble Notes and Queries 1990; 8: 2.

19. Boon-Langedijk C. In den Niederlanden verwendete Messing- und Silberfingerhüte vom Spätmittelalter bis 1900. Rund um den Fingerhut 2004; 38/39: 4.

20. Pelham Burn D. Early Thimbles. Thimble Collectors International, 2001. pp. 28.

Holmes: ‘Early Thimbles’ pp. 15, ‘Thimbles in Germany’ pp. 24, ‘Thimbles in France’ pp. 65 and ‘Brass Thimbles’ pp. 133..

Addendum 1/2013

Between 2008 and 2010, Prof Roger J.A. Wilson of the University of British Columbia excavated a building in a late Roman/early Byzantine village on the south coast of Sicily at Punta Secca (Ragusa province). The building was built c. 580/600 AD at which time Sicily was already part of the Byzantine empire. During the excavation a bronze thimble was discovered in a sealed and undisturbed occupation layer dated by coins to c. 600/625. The thimble was hand dimpled, made from a flat band of copper alloy which was rolled into a cylinder with overlapping ends.

This thimble is clearly an example of an early Byzantine thimble (later thimbles were soldered and even later ones were cast) and may be very similar in construction to the Han thimbles which were found in China.

We are grateful to Prof. Wilson for permission to use his image.

Addendum 9/2014

A silver version of the thimble shown in Fig 71 has been discovered in the collection of the British Museum.

© Trustees of the British Museum

Another recent discovery is a brass thimble which in evolutionary terms lies between the Pelham Burn Type lV thimble in Fig 69 and the silver two part thimble shown in Fig 71.

© Trustees of the British Museum, Portable Antiquities Scheme

Researched and published in 2002/11

Copyright@2011. All Rights Reserved

Magdalena and William Isbister, Moosbach, Germany

Addendum 1/2015

Recent information concerning the Scythian thimble would suggest that the dating of the thimble may not be too robust and that it may, in fact, date to a considerably later period (600-800 AD). Several other similar thimbles or parts of thimbles seem to have been discovered in the Eastern Mediterranean from the same period although the literature relating to these thimbles is not available to us, and some are unpublished. They may have been made in China and exported with the silk and steel needles.

the Evolution of the Thimble

Navigation