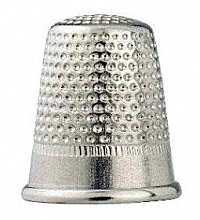

More about Thimbles

Magdalena and William Isbister, Wolf-Dieter Scholz.

Iron is a pure element and rusts easily on contact with air and water. This explains why old iron thimbles are often heavily damaged and rusted. Steel is a compound of iron and carbon and so depending upon the mix of the two elements, the properties of the alloy may change. Other elements may be added to the iron and carbon mix to create other kinds of steels with different properties. For example, the addition of chromium results in a steel that is stain or rust resistant.

Because of the rusting properties of iron many early iron thimbles are no longer in existence. It is not known when the first iron thimbles were made. It was not until the Middle Ages that iron usage began to overtake the use of bronze and copper (1) so that it is unlikely that early thimbles were made of iron. Holmes thought that the earliest iron thimbles known to exist were some finely decorated Italian thimbles (Fig 1) from the 17th to 18th century. These thimbles were decorated with floral patterns and animals, and were rather heavy compared to ordinary thimbles. They were thought to have been made in Bresica in Northern Italy and many still exist in the collection of the Musée Le Secq des Tournelles in Rouen (1).

Fig 1

We have been able to find Turko-Slavic thimbles dating from the 14th to the 15th century that were made of Iron (Fig 2). Interestingly one thimble had a perforated gold ‘plate’ inserted into the top but we have no idea why this should be (Fig 3). It does not seem to be decoration, although the remains of an engraved six pointed star pattern can be seen around it and this seems to correspond to the six peripheral openings in the ‘plate’ (Fig 4).

Fig 2

Fig 3 Fig 4

It seems that prior to the arrival of Christopher Columbus in 1492 there was no need for thimbles in the Americas because women did little sewing, their garments being made of material woven in one piece (2). The thimble was an essential tool of a sail maker, however, and it is highly probable that heavy brass and iron thimbles would have been found on board of the Santa Maria. Later as the Spanish and Portuguese colonialists established settlements in the Americas, it would have been essential to arrange for regular supplies of thimbles from Europe. Following Cortés’ conquest of Mexico in 1521, the colonial records of 1566 document the importation of 500 thimbles (2).

Some time later in England it became necessary to charge duty on thimbles being imported into the country. In 1690 an additional duty was imposed on the wrought-iron content of imported goods with the result that thimbles had to be divided into two groups for tax purposes. One rate was for bronze thimbles and the other was for iron thimbles (3). That this division was necessary suggests that iron thimbles were being imported into England in significant numbers at this time although what they looked like remains unknown.

By the 18th century iron thimbles were being exported from England to North America. Mary Jackson & Son (4), following a fire, reopened their shop and advertised ‘brass and iron thimbles’ and other English cutlery in the Boston News-Letter dated 15th May, 1760. One such imported thimble might have been similar to this 18th century English iron tailors thimble (Fig 5).

Fig 5

In the 19th and 20th centuries iron or iron alloy thimbles were made in many countries. We will document the thimbles that we have been able to identify by probable country of origin although the latter is not always completely clear.

Armenia

Fig 6

This 19th century Armenian iron thimble is inlaid with six 14 karat gold flowers on the top and an intricate inlaid gold floral design on the border and rim. We believe that it has been used as a thimble but whether it was originally made as a thimble or a cap for a gunpowder cartridge container remains unknown.

England

Fig 7 Fig 8 Fig 9

Steel thimbles were made in England in large quantity in the 19th century. Charles Iles and Company of Birmingham, and Olney Amsden and Son of London were two of the largest producers of steel thimbles at the time and marked the thimbles that they sold with their names (Fig 7) or initials (8, left). Iles also made all of the thimbles marked and sold by Abel Morrall of Redditch, Worcester. Iron and steel thimbles are very robust and inexpensive but they rust and are rather hard on the fingers. For this latter reason these thimbles, in England, were usually lined with an inner sleeve of aluminium (Fig 7), brass (Fig 8) or silver (Fig 9). Sewing rings or ‘tailors’ thimbles were made in the same way (Fig 10).

Fig 10

The problem of combining the durability of a ferrous metal alloy with the other advantages of silver thimbles was first addressed by attaching steel tops to silver or gold thimbles. Sometimes the tops came off and in time the softer metal sides of the steel topped thimbles became perforated by prolonged needle use. This problem was solved by Charles Horner, a retail jeweller, who lived in Yorkshire. In 1884 Horner patented (patent number 8954) a steel lined thimble (Fig 11) and the ‘Dorcas’ thimble (Fig 12) was born (5, 6). The outer silver shell (left), the steel middle core (middle), and the inner silver sleeve (right) are well shown in this bisected thimble (Fig 11).

Fig 11

Dorcas thimbles were made in many designs in silver and gold and these early thimbles were simply marked ‘PAT. Later, flatter topped thimbles, produced by bonding the silver and steel sheets before cutting thimble blanks, were marked ‘CH’ – a size number and ‘DORCAS’. This method of manufacture was patented in 1899 (patent number 4658). Soon other thimble makers of the time copied Horner’s idea and made steel lined thimbles of their own. These thimbles were also named; ‘Dreema’ (Henry Griffith and Sons, Birmingham), Dura (Walker and Hall, London) and Doris (Charles Iles and Company, Birmingham).

Fig 12

Dorcas thimbles were also patented (patent number 404,910) in the United States of America (Fig 13) in 1889 although it appears that not many of these thimbles were sold.

Fig 13

Inexpensive thimbles of steel are still made in England today but they are not lined any more (Fig 14).

Fig 14

France

Iron thimbles were in use in France in the 18th century where they were mentioned in a 1723-30, French commercial dictionary (7). By 1819 France was importing thimbles to the value of 800,000 francs (8) and this prompted French thimble makers to try to revive the local thimble making industry. Unusually, thimbles inlaid with gold, were manufactured by inmates at the central prison at Meldu in about 1840 (7).

It is not known who made these 19th century steel thimbles (Fig 15). They are not lined and some authorities (9) claim that they might have been imported from Germany. They are all deep drawn and do not appear to have been temper blued. Some thimbles had decorated borders. The later thimbles have flatter tops.

Fig 15

Fig 16

A steel thimble with a turnover rim and an applied brass leafy band (Fig 16) may have been made in Germany too but the 19th century German steel thimbles usually did not have turned over rims.

Fig 17

Fig 18

These domed top thimbles (Fig 17) are, conventionally, thought to have been made in France and all have French inscriptions around their borders. Later thimbles seem to have flatter tops (Fig 18). They do not have turnover rims and their origin has been questioned (9). The first four are ‘keepsake’ type thimbles and bear the following inscriptions; ‘Toujour fidel’, ‘ M’aimerez vous’, ‘Amour et amitié’, and ‘A toi toujours’. The fifth thimble is an advertising thimble and bears the inscription ‘Fil au Chinois P.V’.

The iron working area, including the town of Iserlohn (see below) in South Westphalia, in the County of Mark passed from Prussia to France in 1807. Thimble makers in the area were thus making ‘French’ thimbles in France and thus the thimbles were French. In 1813, however, the county was returned to Prussia so that ‘French’ thimble making in this region did not last for very long. It may have been long enough, though, to allow the production of ‘French’ type thimbles with French mottos and advertising bands. Production of such thimbles could easily have continued in the region, following return to German rule, and might explain the present difficulty that exists in relation to the determination of the origin of these ‘French’ steel thimbles.

Germany

In the mid 17th century, Iserlohn was a major iron-working town in what is now South Westphalia. Bernhard von der Becke tried to introduce Nürnberg style thimble making to Iserlohn (9) and it is probable that iron thimbles were made for the first time in Germany in this region. Other thimble making factories sprung up in the area and this resulted in the beginning of the demise of thimble making in Nürnberg. The long experience of iron working in the region led to refinements in the technique of manufacture of the iron and steel thimbles. By tempering the steel thimbles it was possible to produce a blue coloured finish that was much more resistant to corrosion than the non-tempered metal, but the finish did not last and few really blue thimbles are seen today. It may be that some of the French thimbles illustrated above (Fig 15) were once blue tempered. With the exception of these blue tempered thimbles it seems that the commonest iron thimbles made in South Westphalia were for sail makers (Fig 19). The makers of the first three thimbles are unknown; the last thimble was made by Johann Moritz Rump of Altena.

Fig 19

Fig 20

This thimble (Fig 20) has a plain dimpled top, a plain flat border with "1914+1915+1916" and a plain flat turnover rim. It was made during the First World War to encourage people to give up gold and silver items for the war effort - the "Gold gab ich fűr Eisen" campaign.

Fig 21

Steel production was soon in progress again after the war and so the manufacture of steel thimbles of various types could be re-established in the region (Fig 21).

Fig 22

Stainless steel thimbles may occasionally be found and they may have been made for medical purposes (Fig 22, left). Some steel advertising thimbles were produced between the wars. ‘COTTON BOLL’ and ‘CÖLNER EHREN-TEPPICH 1917’ were stamped along the borders of the thimbles shown (Fig 22, middle and right).

Fig 23

This thimble (Fig 23) is marked ‘Germany’ on the border and was made before the Second World War because post war thimbles were marked ‘W. Germany’ or ‘West Germany’ prior to unification.

Johann Moritz Rump last showed steel thimbles in his catalogue in 1960 and it is presumed that production stopped around this time (10). Inexpensive steel thimbles are still occasionally made from a ferrous alloy (Fig 24).

Fig 24

Italy

Fig 25

Apart from the 17th century iron thimbles from Italy already mentioned (Figs 1, 25) we have been unable to identify any other Italian iron thimbles. Italy has few mineral resources and this may have limited subsequent iron thimble production.

Russia

Fig 26

We have not found any record of early iron thimbles that were made in Russia. It seems probable that prior to the Soviet era iron was not used very often to make thimbles. It is difficult to date this steel thimble exactly (Fig 26) but it was probably made in Russia prior to the Second World War. A similar type of thimble, manufactured in Germany, is shown for comparison (Fig 26, right).

Fig 27

During Soviet times simple utilitarian thimbles in brass and steel were available in State run shops (Fig 27). The thimble on the left, although inexpensive, has the characteristic Russian rhomboid dimpling sometimes seen on pre revolution thimbles.

Fig 28

Following the fall of communism, the tourist and hence the souvenir trade increased. Plain old Soviet thimbles were ‘modified’ to look more attractive. This simple steel thimble has had a split round black glass bead attached to the top (Fig 28).

Fig 29

Two simple inexpensive contemporary iron alloy thimbles (Fig 29) have mechanical dimpling and round turnover rims. The right one was probably imported from Czechoslovakia.

Fig 30

Two more contemporary ferrous alloy thimbles (Fig 30); an enamel button depicting a bust of Lenin has been attached to the top of the thimble on the right.

Other countries

Fig 31 Fig 32

We have only been able to find contemporary inexpensive steel thimbles from Taiwan (Fig 31) and a sewing ring from Poland (Fig 32).

Gadget thimbles

Fig 33

Whilst there were and still are many types of ‘gadget’ thimbles patented, not all were ultimately made. It has only been possible to find three iron alloy gadget thimbles (Fig 33) and a finger shaped protector (probably made by Johann Moritz Rump) because the majority of these thimbles were either made of brass or non-ferrous metals. The left two thimbles are ‘thread cutters’ and have steel blades. The cutting blade is just visible in the indentations around the top of the left thimble. It was made in Austria and patented by Josef Kunz of Vienna in 1933 (patent number 135791). The next thimble has the cutter in a cut out on the side of the thimble. A thimble with a similar type of aperture was patented in the USA in 1899 by Cecilia Clancy (patent number D31520). The next thimble is a ‘seam ripper’ and was patented in 1985 (patent number D277998). The same idea was, however, patented in the USA in 1894 by George H Carder (patent number 514811). The last thimble is similar to the ‘Trueform’ thimble patented by Horace Bourne in 1904 (patent number 19157).

Other finger protectors

Fig 34 Fig 35 Fig 36

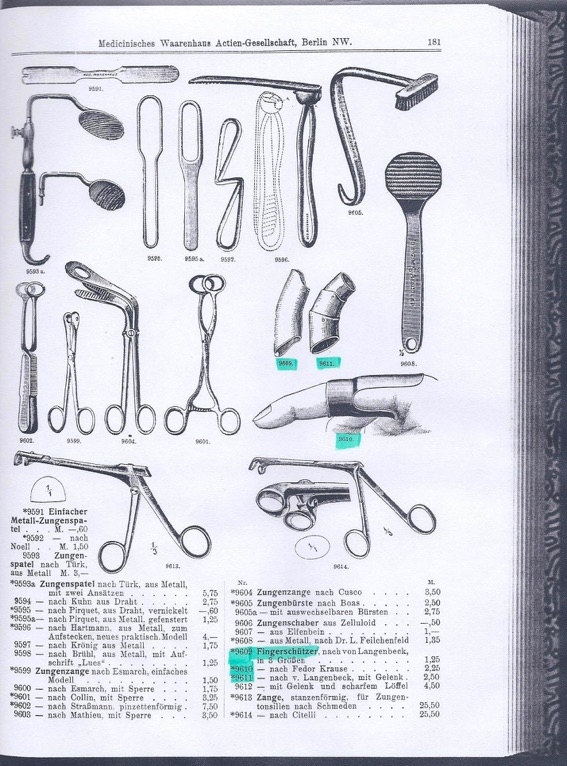

We have found several steel finger guards that have nothing to do with sewing. In days past roof thatchers, in Norfolk, sometimes wore a thimble to protect their fingers. It was quite crudely made and had a sharply formed top (Fig 34). Wigmakers who hand made and knotted hairs individually used a wigmakers thimble to protect their third finger when sewing the foundation of the wig (Fig 35). The three sectioned flexible stainless steel finger guard may be used to prevent a patient biting the finger of a medical attendant when the finger is put into a patient’s mouth to secure the tongue during an epileptic seizure (Fig 36). A drawing of the guard may be found in the Aesculap Surgical Instruments catalogue amongst the other ‘Ear, Nose and Throat’ instruments (Fig 37). Some of these finger protectors had closed ends and the larger ones may have been used in veterinary medicine (Fig 38).

Fig 37

Fig 38

Damascene

Damascening is the art of inlaying gold or silver into a darkly oxidized steel background. The term is derived from the resemblance of the damasked item to the patterns seen in damask silk. We have only seen gold used on thimbles.

Fig 39 Fig 40

Gebrüder Gabler GmbH, of Schorndorf made steel blanks (Fig 39) prior to having the border damascened (Fig 45) in Spain. Steel bands from brass thimbles were similarly (Fig 40) sent to Spain to be damascened (Figs 41-43).

Fig 41 Fig 42 Fig 43

The first two thimbles were made in Spain and have applied steel damascene bands. The first thimble is made of brass and the damascene is very crudely made in a geometric pattern (Fig 41). Both thimbles were made during the last two decades but the nickel silver thimble (Fig 42) is a little later in manufacture and possibly of slightly higher quality. It is a souvenir thimble from ‘Toledo’. The next thimble (Fig 43) is made of brass, has a finely decorated damascene band and was made before the Second World War by Gebrüder Gabler GmbH. The band was probably made in Spain.

Fig 44 Fig 45

Another thimble with a damascene band was made by Gebrüder Gabler GmbH in about 1920 (Fig 44). The thimble is made of silver and is marked 800. The last two thimbles (Fig 45) were also made by Gebrüder Gabler GmbH, but they are made of steel which has been heavily oxidised and into which a gold pattern has been inlayed around the border. The latter two thimbles are thus the only damascene thimbles illustrated here in which the damascene is an integral part of the thimble and not on a separate band.

Fig 46

Reed and Barton, silversmiths of Taunton, MA. made a silver plated thimble (Fig 46) in 1978. It was a plain thimble with a sterling silver damascene plate depicting chickadees in applied bronze and copper. It was signed by the artist John James Audbon. It was marked ‘1978 2nd edition, Limited to 5000, Reed and Barton, Damascene’.

Steel topped thimbles

The first steel topped thimbles seem to have been made in England in the 18th century. Thimbles were made in both silver (Figs 47, 48) and gold (Fig 49) and sometimes the dimpling on the steel top seemed to match the dimpling on the sides of the thimble (Fig 47) and sometimes it did not match (Figs 48, 49). We used to think that this suggested that the top might have been added at a later time but this seems not to have been the case. Hester Bateman (1761-80) made the middle thimble (Fig 48) and ‘HB’ can be seen engraved on the border.

Fig 47 Fig 48 Fig 49

Steel topped brass thimbles were also made in England (Fig 50). Sometimes the steel has rusted away and the thimble seems to have a smooth or irregular top (Fig 51).

Fig 50 Fig 51

Fig 52 Fig 53

Nineteenth century silver (Fig 52) and gold (Fig 53) English thimbles seemed to have been dimpled after the attachment of their steel tops as evidenced by the matching patterns.

Fig 54 Fig 55

Benjamin Halstead was the first American to manufacture steel topped thimbles at the end of the 18th century (Fig 54). It is presumed that Alice Manning owned this 19th century American steel topped thimble (Fig 55). It may have derived its design from Scandinavian steel topped thimbles of the time (see below (Fig 56)) because the steel top does not extend onto the side of the thimble at all.

Fig 56 Fig 57 Fig 58

This two colour gold thimble was made in Sweden in the late 18th century (Fig 56) and it should be noted that the steel top is ‘waffle’ dimpled and inserted into the top of the thimble, as a stone top would be in present times. More modern Swedish steel topped thimbles (Figs 57, 58) also had waffle dimpling although not all tops were mounted like a stone (Fig 57).

Fig 59 Fig 60

Finnish steel topped thimbles (Fig 59) were constructed in a similar way to the Swedish steel topped thimbles. This thimble was made in 1934 by an unknown maker. The thimble depicting Riga harbour (Fig 60) has Latvian silver marks and an unknown maker’s mark. It was made at the beginning of the 20th century and although bearing Latvian marks it may have been made in a neighbouring Scandinavian country.

Steel topped thimbles were available in Russia prior to the revolution (Figs 61, 62) but we have not identifies any steel topped thimbles from the Soviet era. We think that these thimbles were made in Russia.

Fig 61 Fig 62

The silver thimble is made in the English style (Fig 61) but the gold thimble had a Scandinavian waffle dimpled, inset steel top (Fig 62).

Fig 63

Steel topped thimbles were made in France (Fig 63). This tall gold thimble was made in the 18th century and is unmarked.

Fig 64

Inexpensive steel topped thimbles were made at the end of the 19th century and continued on into the 20th century in Austria by Settmacher Brothers in Vienna (Fig 64). The thimbles are made of brass.

We have not been able to identify a single Dutch steel topped thimble although Holland was a major thimble producing country.

Historically steel thimbles seemed to have evolved to offer greater protection to users when sewing heavy materials such as sails or leather. The relative rapidity of failure of gold and silver thimbles to resist prolonged needle pressure led to the initial development of the steel cap or top for thimbles in England in the 18th century. This method of construction was soon copied by thimble makers in Europe and the ‘colonies’. The invention of the steel lined thimble by Charles Horner at the end of the 19th century resulted in the demise of the steel topped thimble. The process of imbedding gold, or less frequently silver, into steel led to the use of this technique for the decoration of thimbles used for light sewing and in souvenir thimbles.

Acknowledgements

We would like to thank Irina Sotnikova for permission to use the image in Figure 26 (left).

References

1.Holmes EF. A history of thimbles. London: Cornwall Books, 1985. pp. 145.

2.Holmes EF. A history of thimbles. London: Cornwall Books, 1985. pp. 54.

3.Holmes EF. A history of thimbles. London: Cornwall Books, 1985. pp. 146.

4.Holmes EF. A history of thimbles. London: Cornwall Books, 1985. pp. 56.

5.Holmes EF. A history of thimbles. London: Cornwall Books, 1985. pp. 106.

6.Burn DP. Identifying steel-cored thimbles. Dorset Thimble Society, 1993.

7.Holmes EF. A history of thimbles. London: Cornwall Books, 1985. pp. 146.

8.Holmes EF. A history of thimbles. London: Cornwall Books, 1985. pp. 148.

9.Wolber E and Wolber M. Blue steel. Thimble Notes and Queries 1992; 17: 4.

-

10. Scholz W. Iron and steel thimbles. Thimble Notes and Queries 1990; 6: 2.

Holmes: ‘Iron and Steel Thimbles’ pp. 145 and 'Thimbles for Other Uses’ pp. 232.

Researched and published in 2002/11

Copyright@2011. All Rights Reserved

Magdalena and William Isbister, Moosbach, Germany

iron and steel thimbles

Navigation